0

0Gate Valve Overview

Gate valve, also called gate valve, gate valve refers to a valve in which the closing member (gate) moves in the vertical direction of the center line of the passage. Used to connect or cut off the medium.

A globe valve refers to a valve in which the closing member (valve disc) moves along the centerline of the valve seat. According to this form of movement of the valve disc, the change in the valve seat opening is directly proportional to the valve disc stroke. Since the valve stem opening or closing stroke of this type of valve is relatively short, and it has a very reliable shut-off function, and because the change of the valve seat opening is proportional to the valve disc stroke, it is very suitable for regulating flow. Therefore, this type of valve is very suitable for use as a cut-off or regulating as well as throttling.

Instructions For Use

1. The gate valve is a control component in the pipeline system that uses a handwheel to drive the gate plate in the vertical direction of the channel axis to cut off and connect the medium flow. The flow rate cannot be adjusted when fully open or fully closed. It has the advantages of small fluid resistance, small opening and closing torque, and unrestricted medium flow direction. Gate valves are metal sealed valves and are currently widely used in water supply systems.

2. Gate valves/stop valves have internal and external threads, flanges, and welded connections. The shell and gate plate adopt constant temperature hot forging and tempering process, the sealing surface is cut by a high-precision sealing surface special machine, and the sealing test strictly follows the GB/T 8464-2008 "Iron and Copper Threaded Connection Valves" standard. 100% pressure test passed before leaving the factory.

3. The installation of valves must be carried out by professionals with relevant qualifications. The non-axial deviation of the pipelines at both ends cannot be too large, otherwise excessive pipeline installation stress will be generated, leading to failure and damage. The accuracy and effective length of pipe threads strictly comply with the relevant ISO 228 standards. When installing and tightening, the hexagonal or octagonal part on the same side of the thread should be wrenched, and the hexagonal or octagonal part on the other end of the valve should not be wrenched to avoid deformation of the valve. Teflon tape or thread sealing glue must be used for sealing.

4. When installing and tightening the valve, you must use a corresponding torque wrench or pipe wrench. Just screw in the effective thread length. Do not overpress the inner end surface, causing damage to the sealing surface and leakage. To ensure the normal use of the valve, try to install it at the pipeline inlet as much as possible. Install the filter.

5. The gate valve/stop valve handwheel is designed according to the corresponding torque and comes in different sizes. Do not use a larger force arm instead to avoid damaging the valve. The valve stem sealing packing is all polytetrafluoroethylene. If there is abrasion and leakage, the gland can be tightened. Fillers compensate. To replace the packing, the medium pressure needs to be relieved. Gate valves in refrigeration and HVAC systems must use 1.6MPa (or above nominal pressure) specifications.

6. When installing flange gate valves/stop valves, you must ensure that the flange surfaces at both ends of the pipeline are parallel and coaxial, the spacing is appropriate, and the connecting screw holes are corresponding. The deviation should not be too large, otherwise it will affect the valve installation quality and sealing performance.

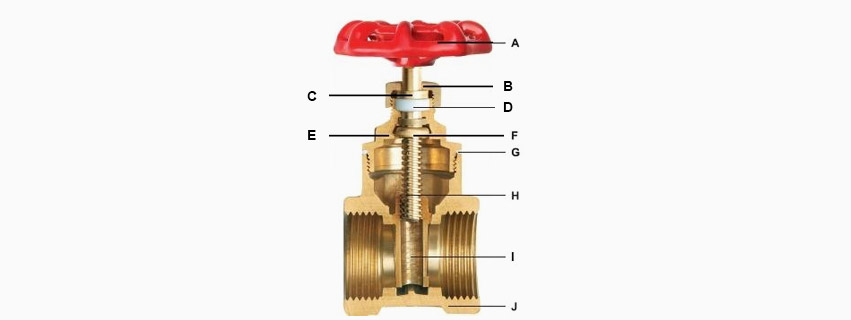

Gate Valve Structure Diagram

A.hand wheel | B.gland | C.pressure ring |

D.filler | E. cap | F. tight circle |

G. gasket | H. stem | I. gate |

J. valve body |

Advantage:

1. Small fluid resistance.

2. Less external force is required for opening and closing.

3. The flow of media is unrestricted.

4. When fully open, the erosion of the working medium on the sealing surface is smaller than that of the stop valve.

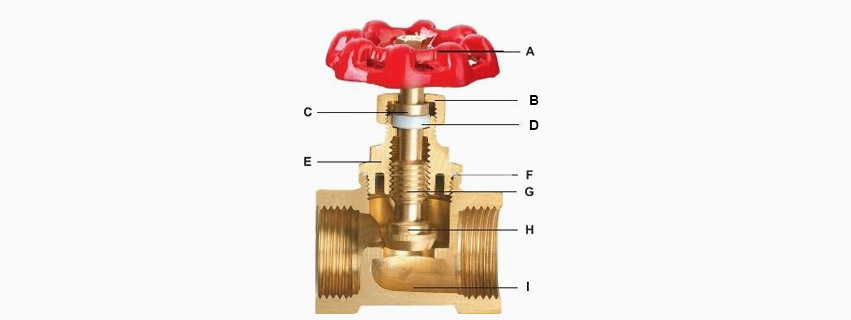

Globe Valve Structure Diagram

A. hand wheel | B. gland | C. pressure ring |

D. filler | E. cap | F. gasket |

G. stem | H. disc | I. valve body |

Advantage:

1. During the opening and closing process, because the friction between the valve disc and the sealing surface of the valve body is smaller than that of the gate valve, it is wear-resistant.

2. The opening height is generally only 1/4 of the valve seat channel diameter.

3. Usually there is only one sealing surface, good manufacturing technology and easy maintenance.

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Tel: 0086-15651696512

WhatsApp: +86-15651696512

Email: leona@js-stone.com

Room 507, Zone C, Mingsai Technology Building, Science and Education City

Integrating the advanced manufacturing industry in China, and from the innovative thinking of the R&D department and the excellence of the production process, our products are trusted by users.

Professional, dedicated, single- minded! Is the company's long and consistent development concept.