0

0

Construction procedures and technical requirements

1. Floor elevation leveling and laying out lines: clean the base layer of the floor and level it. The allowable deviation of unevenness is within 8mm.

2. Layout of waterproof layer: The ground is wet or the first floor of the building should be laid with insulating and waterproof materials.

3. Laying the reflective layer: PE-RT pipes should be laid on insulation boards covered with aluminum foil, with the aluminum foil side facing up. When laying insulation boards, the ground must be flat, and the joints of the insulation layer must be taped firmly.

4. Lay PE-RT pipes, adjust the spacing, and fix the pipes: On the insulation board, the PE-RT pipes are laid ring by ring from far to near. The pipes are fixed on the insulation board using special plastic cards (or templates). The spacing of the plastic clamps is not The maximum size is 500mm, and the corners are no larger than 250mm.

5. Install the water sub-collector and close it with the water sub-collector system: the wall where the water sub-collector is installed should be plastered in advance. The water sub-collector should be fixed on the wall or in a special box. The distance from the ground should be greater than 350mm and should be close to the heating furnace. The location is easily connected to the room hall.

6. Corner insulation: Use special corner insulation strips for corner insulation construction.

7. Pressure test: The test pressure should be 1.5 times the working pressure and not less than 0.6MPa. Under the test pressure, the pressure drop should not be greater than 0.05MPa after stabilizing the pressure for 1 hour.

8. Pour fine stone concrete cushion: After passing the pressure test, the ground pisolite concrete cushion should be poured in season and compacted manually. At this time, the pipeline should maintain a pressure of no less than 0.4Mpa

9. Check the pressure again.

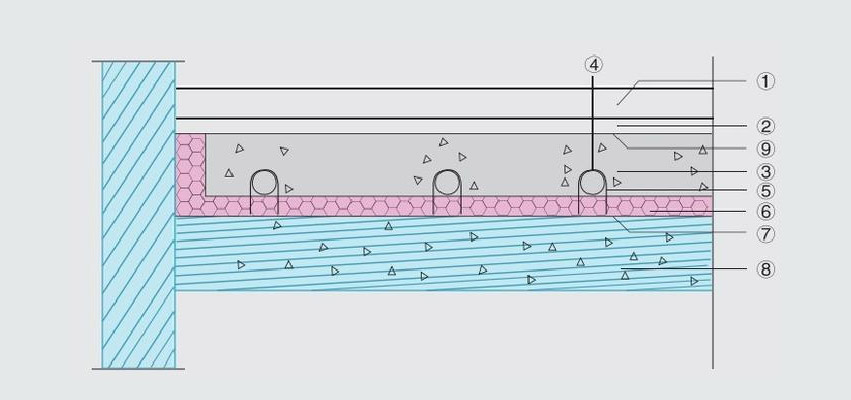

Floor radiant heating system structure diagram

① Ground floor

② Screed

③ Filling:pebble concrete

④ Heating pipe

⑤ Locking nail

⑥ Insulation layer: vertical insulation layer is only provided on the inside of the exterior wall

⑦ Moisture proof layer: only installed on the first layer of soil

⑧ floor slab

⑨ Waterproof layer: only installed on the floor of the floor room

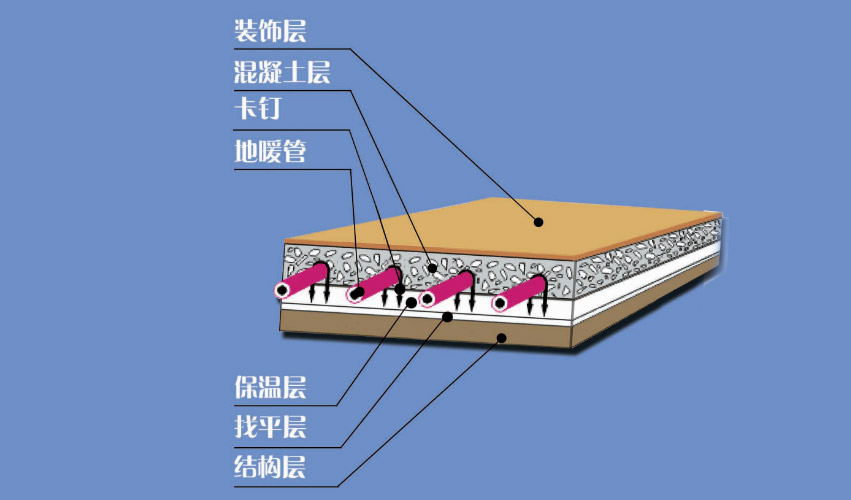

Floor heating construction process

1. Floor elevation leveling and setting lines

2. Clean and level the floor base

3. Laying insulation layer (polystyrene board, etc.)

4. Add reflective film and lay PE-RT pipe

5. Adjust spacing and fix pipes

6. Install water distributor

7. Closed with diverter system

8. Corner insulation

9. Stress test

10. Poured fine stone concrete cushion

11. Pressure test again

12. After passing the test, make the ground surface layer

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Tel: 0086-15651696512

WhatsApp: +86-15651696512

Email: leona@js-stone.com

Room 507, Zone C, Mingsai Technology Building, Science and Education City

Integrating the advanced manufacturing industry in China, and from the innovative thinking of the R&D department and the excellence of the production process, our products are trusted by users.

Professional, dedicated, single- minded! Is the company's long and consistent development concept.